ASNAIL PCP Intelligence 3in1 PCP Sensor

(Torque, Loading and Speed)

ASNAIL PCP Intelligent Monitoring and Management System

is a remote real time monitoring and surveillance system for PCP wells.

Based on the data from automatic tests, wireless remote transmission, central computer real time monitoring, along the surveillance functions with the software, any problematic wells could be identified earlier and problems could be resolved in time, thereby reducing the failure rate of PCP wells, as well as improving the system efficiency.

The main components are as below:

Polished Rod Test sensor

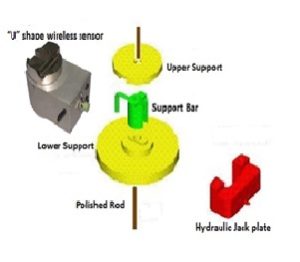

ASNAIL team design and manufactured a U-shaped wireless sensor to measure the polished rod working torque, load and speed.

Wellsite Data Control Panel

Data captured from the field is transmitted to the wellsite data control panel, packed by the PLC then transmitted via wireless to the central working station.

Easy operation: use a hydraulic jack plate to jack up the device, instead of removing manually the anti-off clamp and the tighten clamp and any other complicated procedures, which are usually troublesome.

High efficiency and safety : the whole change-out process takes less than 5 minutes and this could prevent the damage to the rod from clamping or even incidents like lost rod as seen when traditional sensors are used.

Note:

- Upper support: to make polished rod torque and load force through the upper support are transmitted to the sensor components.

- Lower support: to transfer to the sensor torque and load force connected with the PCP wellhead drive, and also play a supporting function.

- Support Bar: a temporary component when replacement or maintenance of the sensor, similar structure of the steel column.

System Software and Functions

PCP wells Intelligent Monitoring and surveillance Software installed in the central computer, upon real timing monitoring all the data from all wells, could automatically calculate the dynamic fluid level, gauge function check and diagnosis, wellhead surface equipment control and optimization of design etc.

PCP Well Status Diagnostic Technology

PCP well Status Diagnosis is to diagnose the common problems such as rod broken, interference of rod and stator, leaking, stuck pump and so forth, by comparison of the theoretical data and the tested data such as the rod torque, load, pump efficiency, along with the analysis of the tested curves and other character curves.

Dynamic Fluid Level Calculation and Automatic Production Computation

Through the combination of two technologies, the on-line monitoring system of the screw pump well and the theoretical calculation model of the PCP, the fluid level calculation and the wellhead comprehensive monitoring and analysis are realized.

Technology of Improving the PCP System Efficiency

Nodal Analysis is applied to calculate the energy consumption and inefficiencies at well bore, pump, string, drive and motor. It is used to analyze parameters and their impact on the energy consumption and efficiency, as well as the percentage of energy consumption for each part over the whole system. This will provide the theoretical factors for improving the PCP system efficiency.